VIDEO: How Maison Dourthe wines create a lasting first impression with Softgard tin overcaps

Trends

January 5, 2026Reading time: 2 minutes

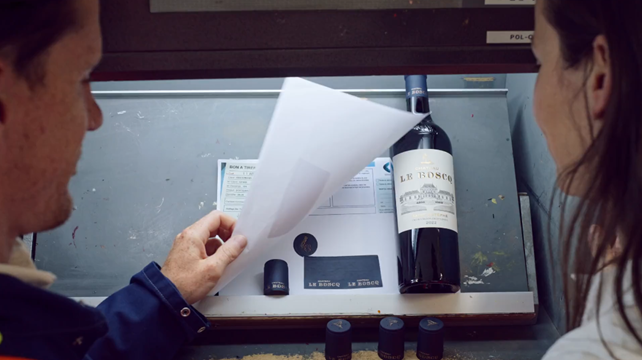

What makes a bottle's first impression last? Discover how Maison Dourthe partnered with Amcor to enhance its premium wine identity through colour research, tailored overcap dimensions, and more sustainable materials by choosing Amcor's Softgard Tin Overcap.

What makes a bottle's first impression last? Discover how Maison Dourthe partnered with Amcor to enhance its premium wine identity through colour research, tailored overcap dimensions, and more sustainable materials by choosing Amcor's Softgard Tin Overcap.

Maison Dourthe: Crafting wine through terroir expression

Maison Dourthe is a historic Bordeaux wine estate founded in 1840 in France. The Maison owns eight different châteaux across the region, including Château Belgrave, which has been classified as a Second Growth since 1855. Each Maison Dourthe vineyard is cultivated using a tailored approach, enabling precise vinification and a distinct identity for each wine produced.

Every wine of the Chateaux embodies a specific expression of where it was grown, clearly defined in taste. To convey this identity through the bottles' appearance, Maison Dourthe wanted an overcap that aligns with the concept behind their wines.

Tin capsule for a lasting first impression

With this objective in mind, the winery chose Amcor as their partner for the re-design of three of their signature wines, each presenting a unique challenge: identifying a specific shade, harmonizing tones, and ultimately reinforcing a premium aesthetic that captures attention and leaves a lasting impression on consumers.

To do this, the Maison chose Softgard, a tin capsule made with over 90%* recycled content that provides a smooth texture with a distinctive tactile experience. As part of the design update, they also chose a shorter length for the overcap. The result is soft to the touch and elegant in appearance.

Through expert forming and finishing, tin overcaps can be customized using a wide variety of textures, embossing, and print effects for differentiation and style. From standard to oversized formats, each overcap reflects craftsmanship and aesthetic harmony.

*According to ISO 14021:2025

The Design to Process journey

Amcor’s design-to-process procedure covers every stage from initial concept to the first production batch, including design development, artwork elaboration to meet production specifications, and color proofing, ensuring consistency and color repeatability across every batch.

Building on over 20 years of collaboration, Amcor supported Maison Dourthe from the earliest stages of the project, advising on colors, textures, and materials to best express the winery’s identity, resulting in three distinct versions of the Softgard tin capsule for its signature wines.

Amcor’s support to address the three specific Dourthe’s challenges consisted of:

-

Color Identification: defining and reproducing consistent tin overcap colors. Based on Pantone or label references, color tests and sample trials were conducted to ensure accuracy. Artwork and color proofs were prepared and validated by the customer prior to production.

-

Tones Harmonization: through expert guidance from the design team, the tin overcap tones were carefully aligned to achieve a cohesive, visually appealing tone-on-tone effect with optimal visual results.

-

Reinforced premium aesthetic and dedicated overcap dimensions: selecting tailored overcap dimensions to enhance the bottle’s premium appearance, attract attention on shelf, and create a lasting first impression for consumers.

Tailored support that goes the extra mile

From concept to execution, the Amcor team provides hands-on support for every stage of your project. With dedicated experts specializing in the wine and spirits market, we offer solution-oriented guidance that combines creativity and technical precision.

We collaborate closely with you from graphic design and artwork to color matching, and we can help you test new solutions directly on your bottling lines. Our Field Technical Service team ensures end-to-end support, guiding you through every stage of the production process: from new product introduction to performance analysis. Our goal is to deliver consistent results, maximize quality, and maintain uninterrupted line efficiency.

Contact us to discover more

Related Insights

VIDEO: For Château Pichon Baron, elegance comes full circle with Softgard Tin Overcaps

November 13, 2025

How can a winery express deep care for the land and elegant craftsmanship? At Château Pichon Baron, in France, this commitment shines through, from the vineyard to the bottle. The estate shares how Amcor’s Softgard, a premium tin overcap made with more than 90% recycled content*, embodies its dedication to both sustainability and refined aesthetics.

How can a winery express deep care for the land and elegant craftsmanship? At Château Pichon Baron, in France, this commitment shines through, from the vineyard to the bottle. The estate shares how Amcor’s Softgard, a premium tin overcap made with more than 90% recycled content*, embodies its dedication to both sustainability and refined aesthetics.

Amcor Capsules incorporates over 90% recycled tin in its capsules for wine, spirits and sparkling foils

May 7, 2024

The strategic move - away from primary content and towards using recycled tin - helps Amcor Capsules deliver its vision for a more responsible wine and spirits packaging industry.

The strategic move - away from primary content and towards using recycled tin - helps Amcor Capsules deliver its vision for a more responsible wine and spirits packaging industry.