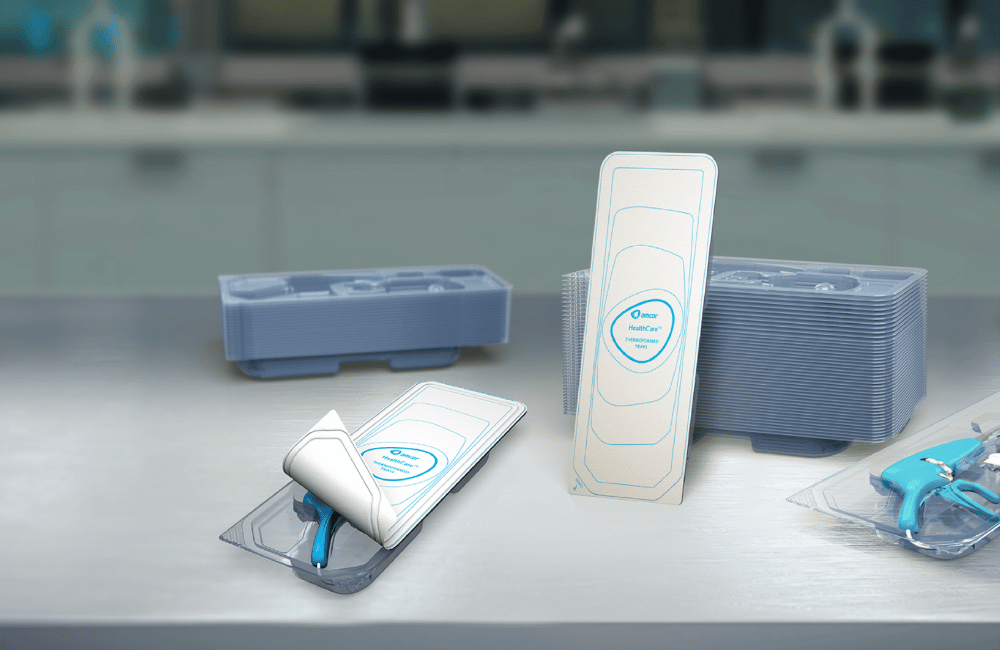

New thermoformed tray capabilities add speed, flexibility, and support for Amcor healthcare customers

Medical

September 23, 2025Reading time: 3 minutes

The expansion of Amcor's thermoforming capabilities worldwide is excellent news for healthcare manufacturers and suppliers. Increased speed and flexibility now accelerate the journey from concept to market for customers in this rapidly growing sector.

The expansion of Amcor's thermoforming capabilities worldwide is excellent news for healthcare manufacturers and suppliers. Increased speed and flexibility now accelerate the journey from concept to market for customers in this rapidly growing sector.

Agile design, prototyping services, cutting-edge production equipment and a wide selection of materials make Amcor a perfect partner for thermoformed tray solutions. Particularly when combined with ongoing guidance from the expert design and support team that is available throughout the process.

Enhanced thermoformed tray production facilities

We invested heavily in the expansion of our Sligo healthcare packaging facility in Ireland, introducing thermoformed tray production in Europe within a Class 7 clean room environment. This drew on our many years of experience in North America, where our thermoformed trays have won multiple packaging innovation awards.

In 2024, we also expanded our thermoforming capabilities in two locations in the United States. We introduced automated, state-of-the-art thermoforming equipment within an ISO Class 7 cleanroom at our world-class healthcare packaging plant in Oshkosh, Wisconsin. This facility produces a wide variety of healthcare packaging formats including tray lidding, offering tray and lid production under one roof to simplify customer orders and audit needs. The Oshkosh facility is in close proximity to Amcor’s Neenah Innovation Center where we have the R&D subject matter experts and the technology to solve the most challenging healthcare applications.

And in Mankato Minnesota, we introduced new automated production capabilities in our dedicated healthcare facility that has long been a center-of-excellence for thermoformed trays. With decades of dedication, the team combines deep expertise with in-house design and tool build services—delivering a complete, trusted solution for our customers.

This adds to the thermoforming capabilities in our healthcare dedicated site in Carolina, Puerto Rico to support local customers. This site also produces a breadth of converted products including tray lidding.

All Amcor facilities specialized in the production of healthcare thermoformed trays operate under the ISO 13485 quality system, the global standard that ensures medical devices are safe, reliable, and meet regulatory requirements. In addition to thermoformed trays, Amcor uniquely offers a true one-stop shop with a wide range of healthcare materials and packaging formats to solve the industry’s packaging challenges.

Expert guidance every step of the way

Our thermoformed tray offering is not solely related to the high quality of our production facilities. Healthcare customers also value our collaborative approach. Our expert design teams can help you improve the performance and efficiency of your trays with solutions tailored to your specific application.

During the product development process, you will have full visibility and touchpoints with our team at every step in the journey. To help streamline the design and development process, for example, your own packaging team will be in direct contact with Amcor’s design and product engineers, conceptualizing tray designs and producing prototypes for your review. Our prototype capabilities range from rapid models for quick design iterations to near production-level units that can be used for product testing early in the development cycle.

Better still, the ability to work with our variety of material options gives you the flexibility to address requirements including carbon footprint reduction for future-proof solutions.

Amcor customers also have access to the Amcor Innovation Centers in Europe and in North America, which leverage our unique, collaborative Catalyst™ approach. This service uses a collaborative end-to-end process, partnering with customers to understand their needs, co-create packaging concepts, develop prototypes, and deliver solutions that meet both performance and sustainability goals.

Supporting your sustainability journey

Our thermoformed trays offering includes options to help you achieve your packaging sustainability goals. Asset™, Amcor’s proprietary life cycle assessment tool, provides you with a rigorous packaging life-cycle assessment to compare the environmental impact of different packaging options and configurations.

An ASSET™ assessment begins with the source of raw materials, taking into account the energy used to transform them, water consumption, environmental emissions, transportation, and the end-of-life management of packaging. Certified by the Carbon Trust, our ASSET™ model identifies opportunities for improving environmental performance and helps you make informed, fact-based decisions.

Need more information?

Our global healthcare manufacturing footprint, unmatched material science expertise, and know-how across the entire healthcare value chain can provide bespoke thermoformed tray solutions that perfectly meet your needs.

Alternatively, visit our product page to find out more and book a meeting with one of our healthcare packaging experts.

Want to create innovative medical packaging with us?

Want to know more about our medical packaging? Contact our healthcare packaging experts and book a virtual coffee with them.

Related Insights

Healthcare™ thermoformed tray capabilities now in Europe

August 3, 2022

A recent investment in our healthcare packaging site in Ireland, brings the addition of thermoformed trays to the Amcor healthcare portfolio in Europe.

A recent investment in our healthcare packaging site in Ireland, brings the addition of thermoformed trays to the Amcor healthcare portfolio in Europe.

Amcor HealthCare™ OrthoSecure® Thermoformed Trays for Class III medical devices

November 14, 2022

Amcor has developed a material for thermoformed medical trays that provides the required product integrity, yet reduces the abrasion risk by combining the benefits of trays, foams and liners into one single solution. Amcor HealthCare™ OrthoSecure® Thermoformed Trays is a simplified Class III Medical Device Packaging that provides all the necessary benefits without the extra cost.

Amcor has developed a material for thermoformed medical trays that provides the required product integrity, yet reduces the abrasion risk by combining the benefits of trays, foams and liners into one single solution. Amcor HealthCare™ OrthoSecure® Thermoformed Trays is a simplified Class III Medical Device Packaging that provides all the necessary benefits without the extra cost.

Why collaboration is at the heart of creating medical thermoformed tray solutions

October 10, 2022

Amcor has invested in the expansion of our Sligo (Ireland) healthcare packaging facility, adding thermoforming capabilities in Europe. This new capability in Europe builds on years of experience in North America, where our thermoformed trays have won multiple packaging innovation awards.

Amcor has invested in the expansion of our Sligo (Ireland) healthcare packaging facility, adding thermoforming capabilities in Europe. This new capability in Europe builds on years of experience in North America, where our thermoformed trays have won multiple packaging innovation awards.